PROFILE

The company was founded in 1993. The company covers an area of 50 acres and has a construction area of more than 20,000 square meters. It has more than 100 employees and a loyal, reliable and experienced production, technology and quality management team.

Read moreyear

Founded

+

Years of production experience

people

More than 100 employees

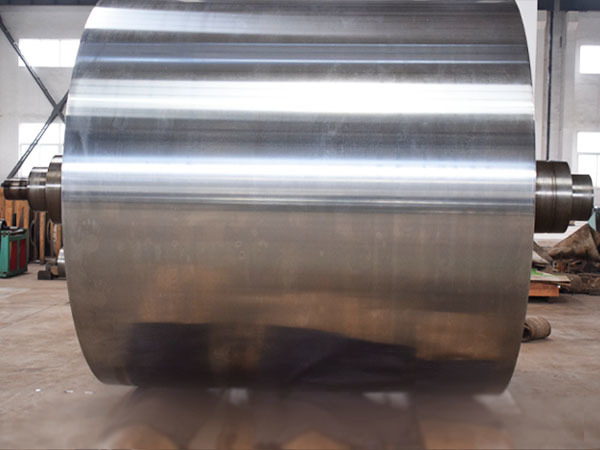

XINGDA MACHINERY STEEL ROLLER

Products are suitable for papermaking, metallurgy, leather, printing and dyeing, rubber and plastics, textile machinery, food processing and other industries

The company mainly produces steel dryers, electroplating dryers, super mirror dryers and various steel rollers that belong to the first category of pressure vessels, which are suitable for papermaking, metallurgy, leather, printing and dyeing, rubber and plastics, Textile, food processing and other industries. All important processes of the product, such as cutting, riveting, gold processing, heat treatment, electroplating surface treatment, etc., can be completed independently by our company.

Contact usNEWS

Focus on company dynamics, release timely information, welcome your attention!

2022-01-24 20:45

How to maintain and maintain the vulcanization drum?

Vulcanizing drum is also a common mechanical equipment, its application range is also very wide, and there are many advantages. Because of this, it is very popular in the market. And according to the current situation, its market space is also very large. However, the maintenance and maintenance of the vulcanization drum is equally important for the enterprise. In order to avoid problems during use, the editor will talk about the maintenance method.

Read more2022-01-24 20:29

The main failure of paper machinery

The equipment flow of the paper machine production line is long and the specifications and models are complex. Any damage to any component or single machine in the process will lead to the complete shutdown of papermaking, which will cause certain economic losses to papermaking enterprises. Therefore, it is necessary to understand the frequent failures of papermaking machinery in order to take preventive measures in time.

2022-01-24 20:28

(1) The working temperature of the bearing position of the press roll is high. During normal production and operation, the bearing is in a sealed environment. The normal operating temperature is relatively high, and each component of the bearing will be heated and expanded, which is more likely to cause the material to invade and adhere, causing the rolling element of the bearing to run. The resistance increases, causing small pits or pit-like spalling on the surface of the rolling element, and the spalled metal will adhere to the surface of the raceway and cause the surface of the raceway to be roughened.

2022-01-24 20:27

What are the common problems in the operation of the vulcanizing drum?

There are actually many problems in the operation of the vulcanizing drum, but for those who do not understand, they will find it very troublesome, and they do not even know how to solve them. I will definitely tell you about the related issues. Otherwise, it will often fail when using it. Here we will talk about common problems and their solutions, and know how to solve them when encountering such a thing in the future.